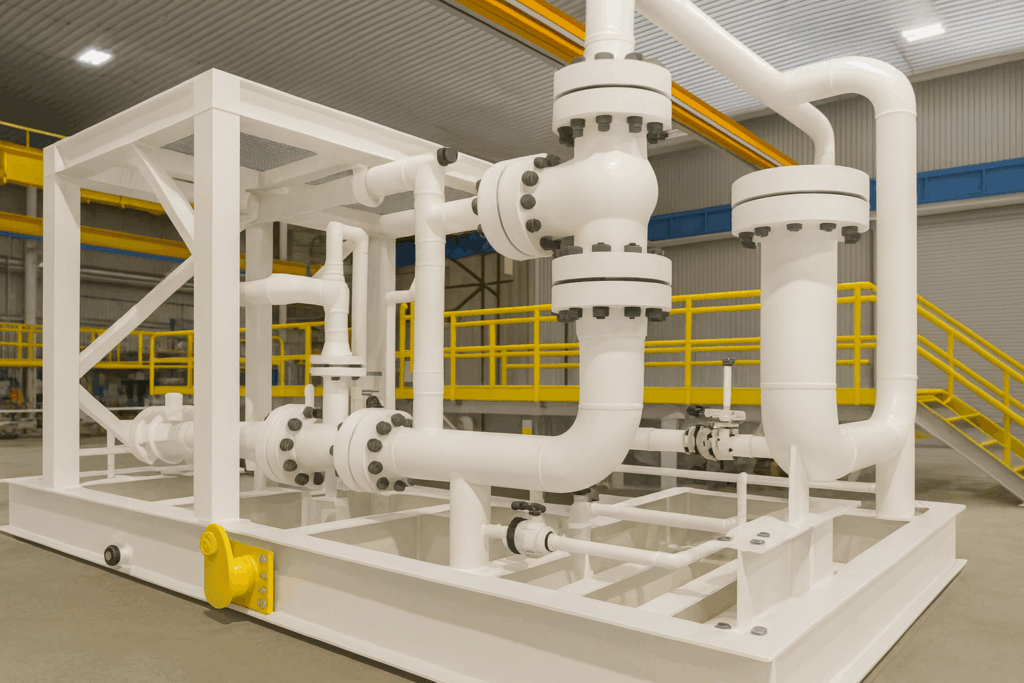

A skid system is a pre-assembled process unit built on a structural base. It includes all the piping, valves, tanks, and instrumentation needed to perform a specific function—all integrated and mounted off-site. When it shows up, it’s ready to connect and go.

Skids save time in the field, reduce installation costs, and make complex systems easier to manage.

Why Use Plastics for Skid Systems?

Plastic materials offer a number of advantages, especially in environments where corrosion, weight, and chemical compatibility are concerns.

- Corrosion resistance for harsh chemical applications

- Lightweight construction makes transport and installation easier

- Long-lasting performance with minimal maintenance

- Excellent chemical compatibility with a range of industrial fluids

- More affordable than stainless steel in many applications

We use thermoplastics like HDPE, PP, PVC, CPVC, and PVDF depending on the specific requirements of your system.

What We Build

We fabricate a wide range of custom skid systems for plastic piping and process equipment. That includes:

- Chemical feed skids

- Filtration and treatment skids

- Pump and valve assemblies

- Flow monitoring and control stations

- Custom-built modular process skids

Each project is engineered to your specifications, fully assembled at our facility, and tested before delivery.

Industries We Work With

Our plastic skid systems are used in facilities across a wide range of industries, including:

- Chemical processing

- Water and wastewater treatment

- Pharmaceuticals

- Food and beverage

- Semiconductor manufacturing

- Power generation

If your system needs to stand up to tough environments—or meet strict cleanliness standards—we can help you design a solution that works.

Built Off-Site, Ready to Work

Let’s Talk

If you’re planning a new system or looking to simplify an existing one, let’s talk about how a custom plastic skid can help. Our team is ready to work with you from design through delivery.

Contact us to get started or to learn more about what we can build for your operation.